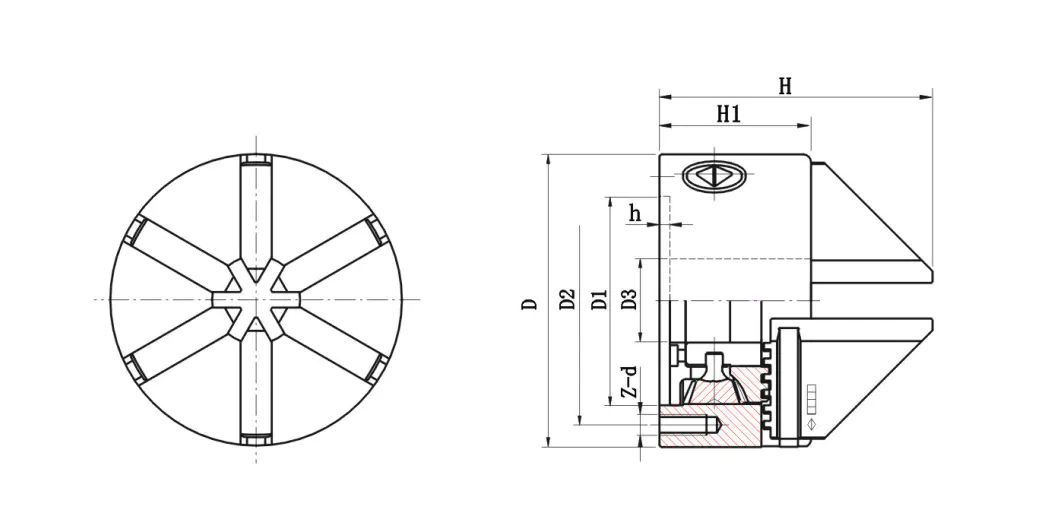

K13 Awl Six-jaw Self-centring Chucks

- Category: Self-Centering Chuck Structure

- Product description:High Quality Awl Six-Jaw Chucks Exporters is a China Custom Six-Jaw Self-Centring Chucks Company, The design of a six-jaw self-centering chuck plays a critical role in enhancing its performance. Manuf

|

SPEC./MODEL |

D1 |

D2 |

D3 |

H1 |

H |

h |

z-d |

Max.Speed |

Net WT. |

|

100 |

72 |

84 |

22 |

55 |

74.5 |

3.5 |

3-M8 |

1250 |

3.5 |

|

112 |

80 |

95 |

32 |

58 |

104.5 |

4 |

3-M8 |

1200 |

4.2 |

|

125 |

95 |

108 |

30 |

60 |

85 |

3.5 |

3-M8 |

1200 |

5 |

|

160 |

130 |

142 |

45 |

65 |

95 |

5 |

3-M10 |

1000 |

8.8 |

|

167 |

130 |

147 |

60 |

65 |

108 |

5 |

3-M10 |

1000 |

9.2 |

|

200 |

165 |

180 |

65 |

25 |

109 |

5 |

3-M10 |

- |

15 |

|

250 |

206 |

226 |

80 |

80 |

120 |

5 |

3-M12 |

- |

24 |

|

315 |

260 |

285 |

100 |

90 |

153 |

6 |

3-M16 |

- |

38 |

|

400 |

340 |

368 |

130 |

100 |

172 |

6 |

3-M16 |

- |

70 |

|

500 |

440 |

465 |

200 |

115 |

202 |

6 |

6-M16 |

- |

115 |

|

630 |

560 |

595 |

260 |

130 |

218 |

7 |

6-M16 |

- |

210 |

The Design of Six-Jaw Self-Centering Chuck to Improve Its Performance

In the realm of machining operations, achieving precise centering and secure gripping of workpieces is paramount for obtaining accurate and high-quality results. The design of a six-jaw self-centering chuck plays a critical role in enhancing its performance.

(1)Increased Number of Jaws:

The fundamental design aspect of a six-jaw self-centering chuck lies in the increased number of jaws compared to traditional chucks. By employing six jaws, this design ensures a greater number of contact points with the workpiece, leading to improved gripping and enhanced stability. The increased jaw count enables better load distribution, reducing the risk of workpiece deflection and enhancing overall machining accuracy.

(2)Independent Jaw Movement:

A notable feature of six-jaw self-centering chucks is the capability of independent jaw movement. Each jaw can be adjusted individually, allowing for precise alignment with the workpiece's center. This independent adjustment feature enables accommodating irregularly shaped or asymmetrical workpieces, enhancing the chuck's versatility and centering capabilities.

(3)Symmetrical Jaw Arrangement:

The arrangement of six jaws in a symmetrical pattern is another key design aspect of a six-jaw self-centering chuck. The symmetrical distribution ensures balanced clamping forces around the workpiece, resulting in improved concentricity and overall centering accuracy. The symmetrical arrangement also helps mitigate any imbalances caused by uneven workpiece weight or irregular shapes.

(4)Synchronization Mechanism:

To achieve simultaneous jaw movement, six-jaw self-centering chucks utilize a synchronization mechanism. This mechanism ensures that all six jaws move uniformly, enabling precise centering of the workpiece. Typically, gears, levers, or a master jaw serve as a reference point for synchronizing the movements of the remaining jaws. This synchronization feature ensures consistent and accurate centering, reducing the chances of misalignment during machining operations.

(5)Enhanced Gripping Power:

The design of six-jaw self-centering chucks focuses on maximizing gripping power. The increased number of jaws and contact points significantly improves the chuck's ability to securely grip the workpiece. This enhanced gripping power is particularly beneficial for handling heavy, large-sized, or irregularly shaped workpieces, providing stability and minimizing workpiece deflection during machining operations.

(6)Interchangeable Jaws:

Many six-jaw self-centering chucks incorporate interchangeable jaws, further enhancing their performance and versatility. Different types of jaws, such as standard, soft, or stepped jaws, can be easily exchanged to accommodate various workpiece shapes and sizes. This interchangeability allows for customized gripping solutions based on specific machining requirements, expanding the chuck's capabilities and adaptability.

(7)Quick Jaw Change Systems:

To enhance productivity and reduce setup time, modern six-jaw self-centering chucks feature quick jaw change systems. These systems allow for rapid jaw replacement without the need for complex adjustments or disassembly. The ability to quickly switch between different jaw configurations enables operators to adapt to changing workpiece requirements efficiently, increasing overall operational efficiency.

(8)Rigidity and Stability:

The overall design of a six-jaw self-centering chuck focuses on achieving rigidity and stability during machining operations. The chuck body is constructed using robust materials, to withstand heavy loads and resist deformation. Furthermore, precision machining techniques are employed to ensure tight tolerances and high accuracy, contributing to the chuck's stability and overall performance.

By incorporating innovative design elements, manufacturers continue to refine and improve six-jaw self-centering chucks, meeting the evolving demands of modern machining operations and ensuring precise and reliable centering of workpieces.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name:

phone:+86-576-82356788

Whatsapp:8657682356788

Email:tp@tpchuck.com

Add:Luqiao District, Taizhou City, Zhejiang Province, China.