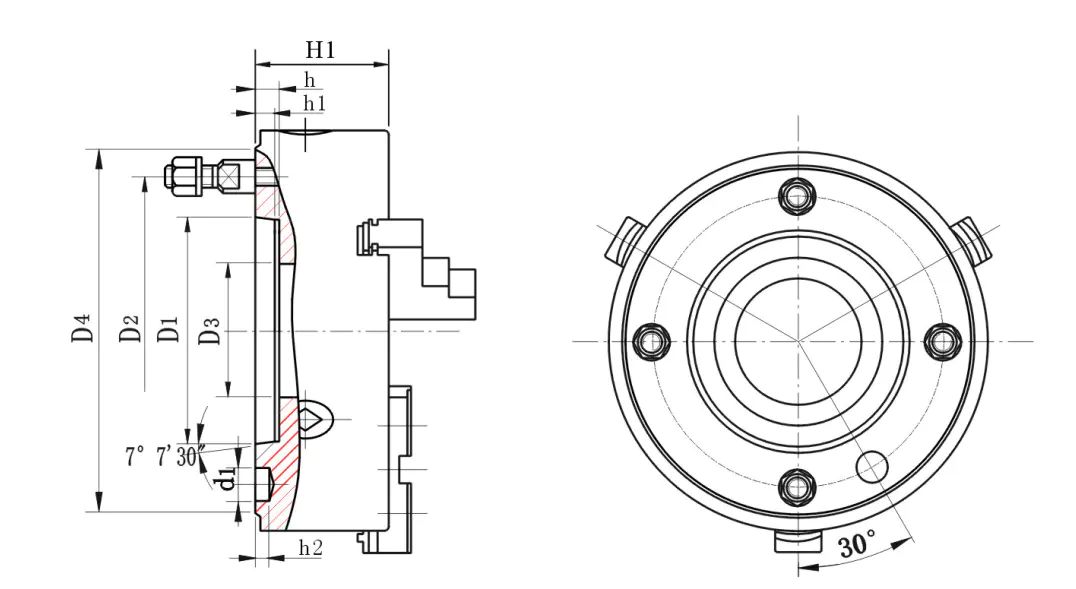

K11 direct mounting three-jaw self-centring chucks (From c mounting with studs and locknuts)

- Category: Self-Centering Chuck Structure

- Product description:Tianyi is High Quality Three Jaw Self-Centring Chucks Factory and Wholesale Self-Centring Chucks Suppliers. Machine tools play a vital role in various industries, the connection between rods and other

|

SPEC./MODEL

|

D1

|

D2

|

D3

|

D4 | H1 | h |

h1

|

z-d |

Net WT.

|

| 125/D3 | 53.975 | 70.6 | 25 | 92 | 63 | 13 | 10 | 3-M10x1 | -- |

| 125/D4 | 63.513 | 82.6 | 25 | 117 | 63 | 13 | 10 | 3-M10x1 | -- |

| 160/D3 160A/D3 | 53.975 | 70.6 | 40 | 92 | 76 | 13 | 10 | 3-M10x1 | 10 |

| 160/D4 160A/D4 | 63.513 | 82.6 | 40 | 117 | 70 | 13 | 10 | 3-M10x1 | 10 |

| 160/D5 160A/D5 | 82.563 | 104.8 | 40 | 146 | 73 | 15 | 12 | 6-M12x1 | 10 |

| 200/D4 200C/D4 200A/D4 | 63.513 | 82.6 | 50 | 117 | 86 | 13 | 10 | 3-M10x1 | 17 |

| 200/D5 200C/D5 200A/D5 | 82.563 | 104.8 | 50 | 146 | 86 | 15 | 12 | 6-M12x1 | 17 |

| 200/D6 200C/D6 200A/D6 | 106.375 | 133.4 | 50 | 181 | 86 | 16 | 13 | 6-M16x1.5 | 17 |

| 250/D5 250C/D5 250A/D5 | 82.563 | 104.8 | 70 | 146 | 95 | 15 | 12 | 6-M12x1 | 31 |

| 250/D6 250C/D6 250A/D6 | 106.375 | 133.4 | 70 | 181 | 98 | 16 | 13 | 6-M16x1.5 | 32 |

| 250/D8 250C/D8 250A/D8 | 139.719 | 171.4 | 80 | 225 | 98 | 18 | 14 | 6-M20x1.5 | 32 |

| 315/D6 315C/D6 315A/D6 | 106.375 | 133.4 | 100 | 181 | 106 | 16 | 13 | 6-M16x1.5 | 51 |

| 315/D8 315C/D8 315A/D8 | 139.719 | 171.4 | 100 | 225 | 106 | 18 | 14 | 6-M20x1.5 | 51 |

| 315/D11 315C/D11 315A/D11 | 196.869 | 235.0 | 100 | 298 | 106 | 20 | 16 | 6-M22x1.5 | 53 |

| 400/D8 400C/D8 400A/D8 | 139.719 | 171.4 | 130 | 225 | 118 | 18 | 14 | 6-M20x1.5 | 81 |

| 400/D11 400C/D11 400A/D11 | 196.869 | 235.0 | 135 | 298 | 118 | 20 | 16 | 6-M22x1.5 | 81 |

| 500A/D11 | 19.869 | 235.0 | 190 | 298 | 135 | 20 | 16 | 6-M22x1.5 | 159 |

| 500A/D15 | 285.775 | 330.2 | 210 | 403 | 135 | 21 | 17 | 6-M24x1.5 | 148 |

| 630A/D11 | 196.869 | 235.0 | 190 | 298 | 154 | 20 | 16 | 6-M22x1.5 | 285 |

| 630A/D15 | 285.775 | 330.2 | 260 | 403 | 154 | 21 | 17 | 6-M24x1.5 | 270 |

| 800A/D15 | 285.775 | 330.2 | 280 | 403 | 175 | 21 | 17 | 6-M24x1.5 | 455 |

| 1000A/D20 | 412.775 | 463.6 | 400 | 520 | 188 | 23 | 19 | 6-M27x2 | 710 |

Benefits of Using Cam Lock Fittings to Connect Rods in Machine Tools

Machine tools play a vital role in various industries, enabling precision machining and manufacturing processes. Within these machines, the connection between rods and other components is crucial for their overall performance. Cam lock fittings have emerged as a popular choice for connecting rods in machine tools due to their numerous benefits. This article explores the advantages of using cam lock fittings.

(1)Fast and Secure Connections

One of the primary advantages of cam lock fittings is their ability to provide fast and secure connections. The design of cam lock fittings allows for rapid assembly and disassembly, reducing setup time and improving operational efficiency. The locking mechanism ensures a secure connection, preventing any unwanted movement or disengagement during operation, even in high-vibration environments.

(2)Easy Installation and Alignment

Cam lock fittings are known for their user-friendly installation process. They feature a simple design that allows for easy alignment and engagement of the rods. With a quick and straightforward locking mechanism, operators can swiftly connect and disconnect rods without the need for additional tools or complex procedures. This ease of installation saves valuable time and effort in machine setup and maintenance.

(3)Versatility and Compatibility

Another notable benefit of cam lock fittings is their versatility and compatibility. These fittings are available in a wide range of sizes and configurations, making them suitable for various types of rods commonly used in machine tools. They can accommodate different diameters, shapes, and materials, providing a versatile solution for connecting rods of different specifications. This compatibility simplifies inventory management and reduces the need for multiple types of connectors.

(4)Repeatability and Consistency

Consistency and repeatability are essential factors in machine tool operations. Cam lock fittings excel in providing repeatable and consistent connections. Once properly installed, the fittings maintain their alignment and engagement, ensuring precise positioning of the rods. This level of repeatability is crucial in achieving accurate and consistent machining results, reducing the need for frequent adjustments or rework.

(5)High Load Capacity

Cam lock fittings are designed to withstand high loads and provide reliable performance even under heavy-duty conditions. The locking mechanism offers exceptional holding power, ensuring that the rods remain securely connected, even during demanding machining processes. This high load capacity enhances the overall stability and reliability of the machine tool, contributing to improved productivity and extended tool life.

(6)Enhanced Safety

Safety is a top priority in any industrial setting, and cam lock fittings contribute to a safer working environment. The secure locking mechanism eliminates the risk of accidental disconnection, which can lead to hazardous situations. By providing a reliable and stable connection, cam lock fittings reduce the likelihood of component failure, preventing workplace accidents and potential damage to the machine and surrounding equipment.

(7)Reduced Downtime

Minimizing downtime is crucial for maintaining productivity and meeting production targets. Cam lock fittings contribute to reduced downtime by simplifying rod connections and facilitating quick replacements or adjustments. With their easy installation and disassembly process, operators can swiftly swap out rods or make necessary changes, minimizing the impact on production schedules and improving overall operational efficiency.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name:

phone:+86-576-82356788

Whatsapp:8657682356788

Email:tp@tpchuck.com

Add:Luqiao District, Taizhou City, Zhejiang Province, China.